Category

Subcategory

AW-4600FX #2755

For sale as a renovation object Every third time the gripper plastic breaks See more info in pictures

BOSS NE2/63 #2753

New oil and filter. New welding tape. New emergency stop button. New hinges and spring mounts. Test run u.a. vac-value 5.

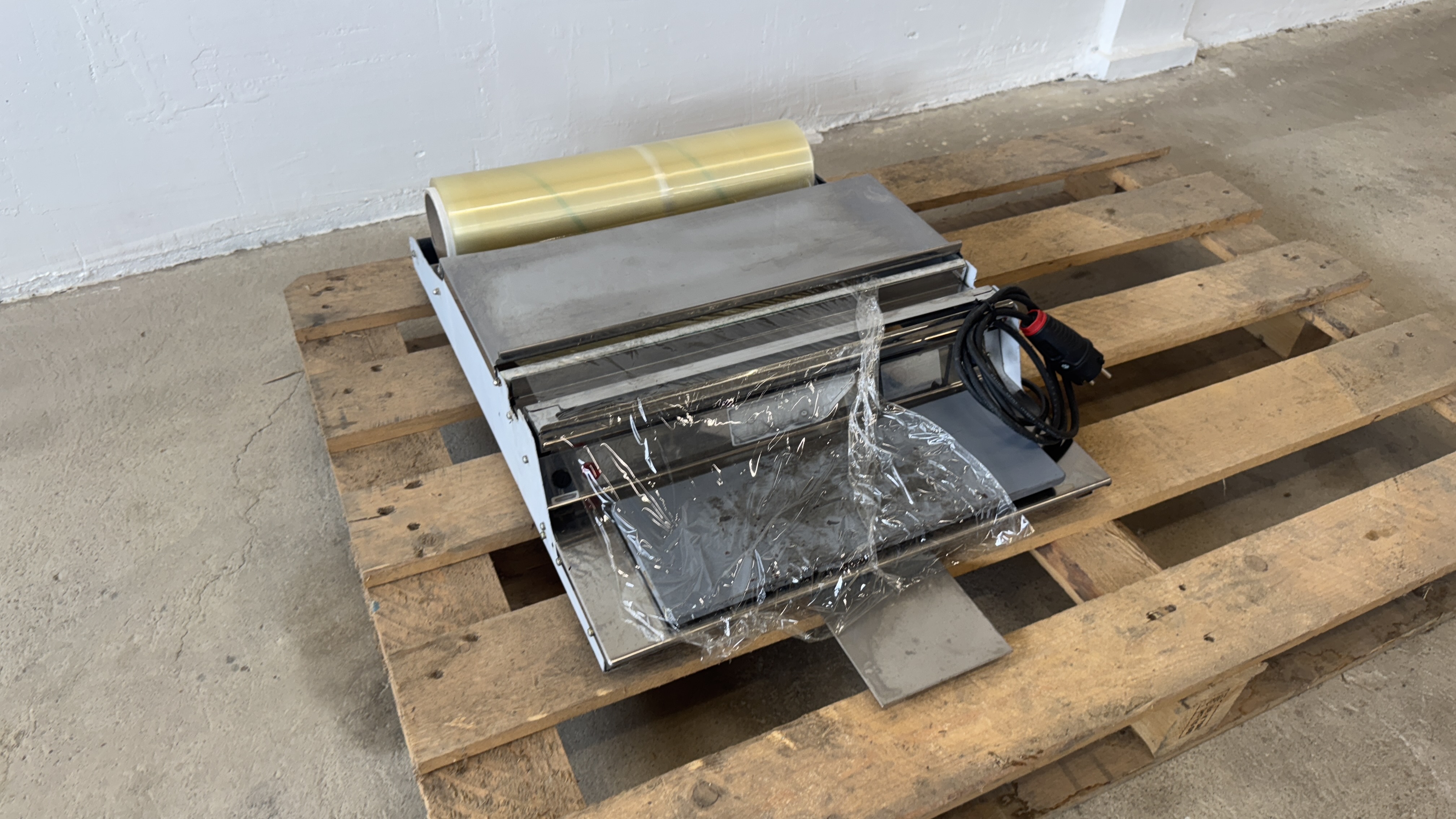

Wrapper Digi AW4600 #2611

Tested and works well. The screen flickers a little, but works great.

Vacuum machine VC999 #2579

New air hoses, New air bellows, New Teflon tape, Changed the order of the belts, 2 new potentiometers, Changed the input air pressure regulator, New oil in the vacuum pump, New silicone strips under the welding beams, 1 new switch for emergency stop, Renovated/cleaned vacuum and pressure valve.

Flowpack GNA -2002 #2574

Adjusted compressed air sensor. Installed new pressure gauge. Installed a new position sensor. Made a new protective plate underneath. Made a new protective plexiglass on top.

Tray sealer (paper trays) MPE TT600 #2535

Seems to work fine, we haven't tested with paper trays

Vacuum machine Komet SD 520 #2498

Welded and milled arms for the counterweights and arranged locking mechanism for the axles, Sealed all possible sources of leakage with silicone and welded crack in the table. Vacuum value: 6-7mbar both sides