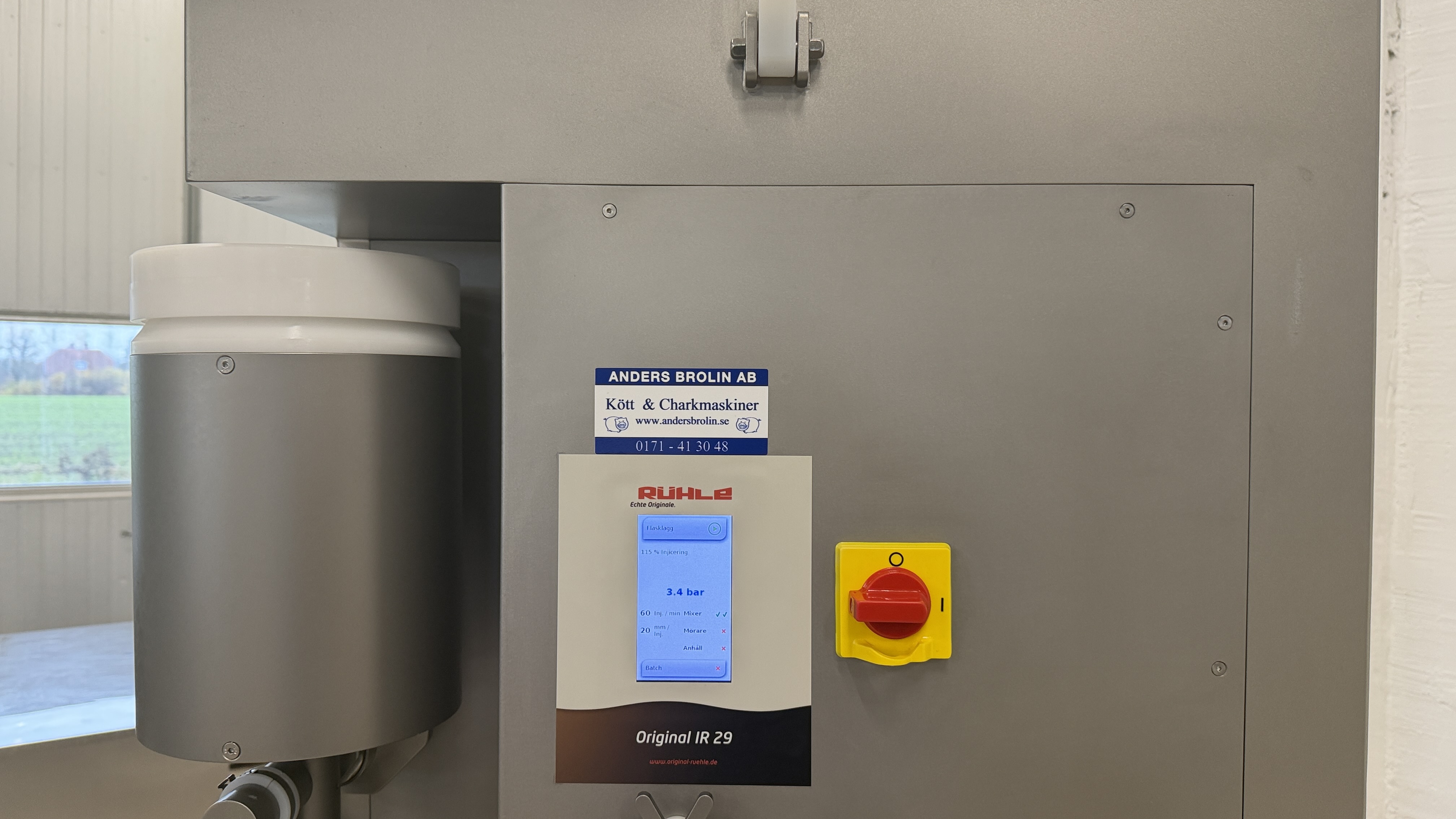

Ruhle IR 29 - 2000kg/h

Images

Videos

Ruhle IR 29 - 2000kg/h

Kontakta oss för pris

Beskrivning

Tekniska data

Maskinlängd 1 228 till 2 072 millimeter

Maskinbredd 911 millimeter

Maskinhöjd 1 890 millimeter

Maskinvikt 440 kilogram

Arbetskapacitet 2 000 kilogram per timme

Stickfrekvens 24 eller 48 per minut

Bandbredd 360 millimeter

Nålrader 2

Genomgångshöjd 280 millimeter

Injektionsmängd 3 till 80 procent

Arbetstryck 0,3 till 4,2 bar

Anslutningseffekt 400 volt, 6,1 kilowatt, 16 ampere

Bandmatning 20, 30 eller 40 millimeter

En mångsidig rotationspump

Byggd som en nedsänkt pump är denna apparat verkligen mångsidig. Pumpen arbetar med låg pulsering och är självsugande, torrkörningssäker och självdränerande ända till sista droppen. Den snabbinsugande geometrin hos pumphjulet möjliggör luftborttagning, vilket förbättrar saltlaken. Därmed finns fullt tryck tillgängligt vid nålarna redan från första slaget inom urvalsområdet mellan 0,3 och 4,2 bar, vilket i sin tur möjliggör noggranna injektionsvolymer från 3 % till 80 %.

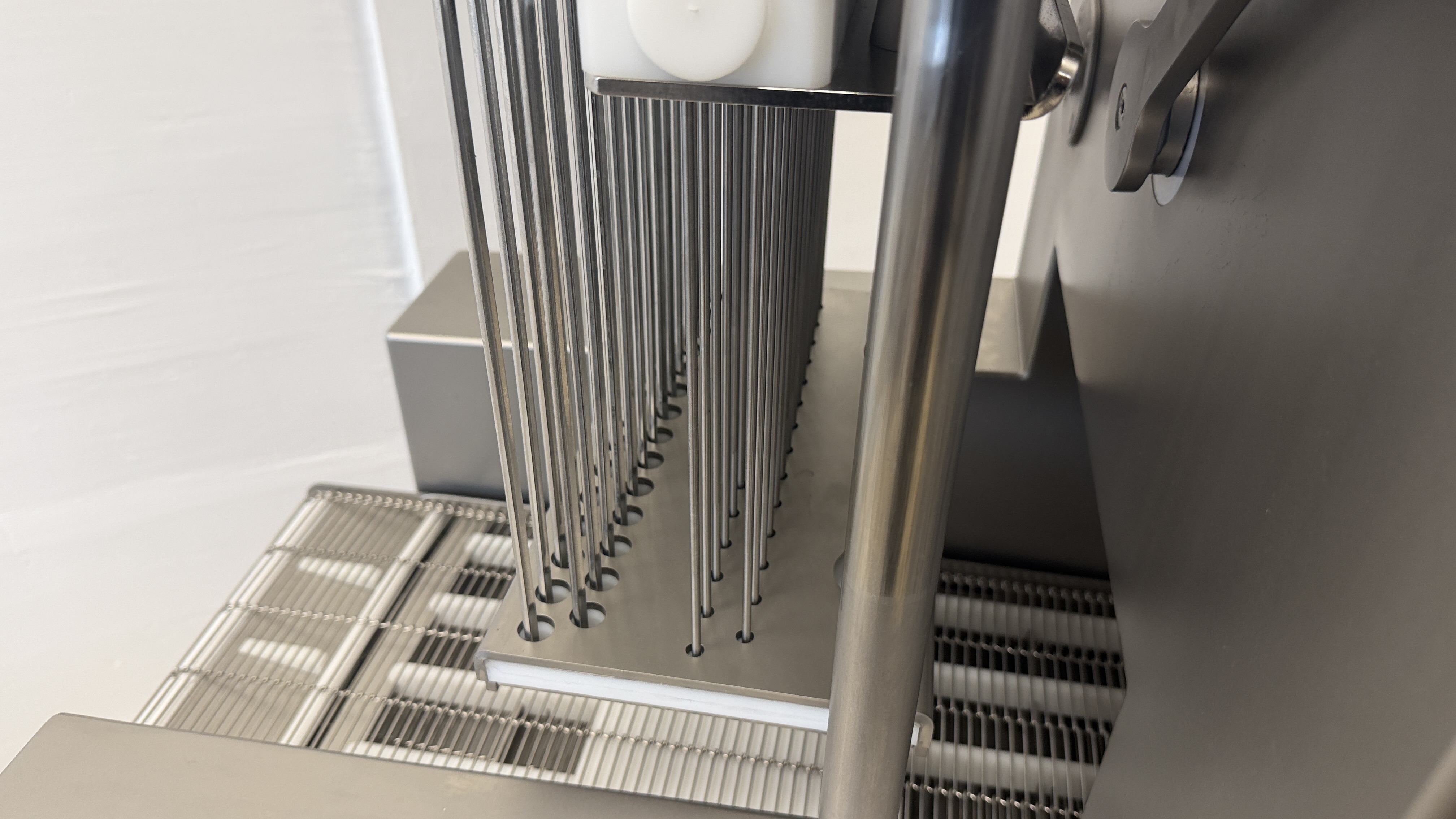

Ennålsstyrning

Så snart en nål träffar köttets yta öppnas vätskeintaget. Om nålen träffar ben stängs vätskeintaget för att förhindra att för mycket vätska samlas på en plats. När nålen tränger igenom köttet utan att möta benmotstånd injiceras vätskan tills nålen kommer ut på köttets undersida. På detta sätt fördelas saltlaken jämnt genom hela köttbiten.

Överlägsen hygien

Varje del av denna maskin är utformad för snabb rengöring. Det finns inga svåråtkomliga hörn. Stor vikt har också lagts vid hygien i områden som inte är synliga. Injektorn dräneras helt efter drift eller rengöring. Maskinen kan rengöras, torkas och enkelt ställas undan på mycket kort tid.

Smarta hjälpmedel för drift

En inmatningsramp placerad i vinkel fungerar som ränna för att tippa i köttet. När rampen är placerad plant kan den användas som arbetsyta.

Till exempel kan kärl placeras på ytan för att mata köttet till bandet med minimal ansträngning. Maskinen är byggd för att passa standardvagnshöjd, och manöverreglagen är lättåtkomliga.

Perfekt saltlake med hjälp av jetpumpar

En kraftig jetstråle ger perfekt blandad saltlake på bara en minut. Den fördelar alla kryddor och ingredienser jämnt i vattnet och löser upp dem helt. En svagare jetstråle bibehåller blandningsresultatet under injektionsprocessen, vilket håller kryddor och ingredienser jämnt fördelade under hela härdningscykeln. Eftersom kryddorna ständigt hålls svävande blir köttet jämnt kryddat.

Mjukare kött för större proteinutvinning

Fina vinklade blad skär igenom köttet med kirurgisk precision. Ett upphängningssystem för bladen möjliggör bearbetning av kött med ben. Under processen då fibrerna skärs igenom mjukas köttstrukturen upp, vilket aktiverar aktomyosin – köttets eget mörningsämne. Resultatet är ökad vätskehållning och mörare kött.

Specifikationer

| Tillverkare | Ruhle |

| Modell | IR 29 |

| Skick | Ny |

| Lagernummer | 10629 |